Author Archives: ZIPP GROUP

ZIPPTORK Smart Torque Controller Introduction and Demonstration

ZIPP GROUP Announcement Update

A Message to Our Valued Customers

Concerning the situation generated by the “Coronavirus / Covid-19”, we would like to inform you that all the activities of our company continue to take place normally, so as to guarantee our customers and suppliers the usual working efficiency.

Due to on-going updates concerning the coronavirus, we wanted to let you know how ZIPP GROUP is managing the changes during this time. In common with other companies, our top priorities are to work closely with the Taiwan government recommended directions to obtain any necessary exemptions to keep our facility open, following WHO and CDC recommendations to maintain the safety and wellbeing of our employees.

This is a challenging time for the world, but we remain committed to our customers and our team. We are thankful for the heroic work of healthcare workers and all that support them across the globe.

We know many customers will have critical production deadlines due to the “Coronavirus / Covid-19”. We take this impact seriously. Our sales and service team will reach out to you as we have updates on your orders. We aim to mitigate the possible effects on production.

As always, our sales account managers and customer service teams are fully available to assist as required. Our team is committed to supporting you during this challenging time. We all hope you stay safe and healthy.

We at ZIPP GROUP thank you for your business. Your satisfaction and safety are our number one priority.

Best regards,

ZIPP GROUP Inc.

ZIPP GROUP Announcement

We very much regret to announce to you that after a close review of guidance by global health authorities, and out of an abundance of caution due to the coronavirus disease (COVID-19) outbreak. We have made the difficult decision to withdraw from all the upcoming exhibitions, and international business travels before the fourth quarter of 2020. Since the situation is changing fast, and as new hotspots and outbreaks are reported, airline and travel policies will likely change too. We will continue to update our announcement through all available channels as the situation develops.

All the new products announcement will be presented online through our corporate website, FB fan page, Linkedin, and many other alternative social media. Furthermore, we will be publishing a series of videos explaining our latest product features and functionality with detailed instruction videos on our corporate YouTube channel.

Please accept our apologies for any inconvenience. For those who had plans to discuss business topics or wish to see our latest products in live-action, please feel free to contact us directly by email, and we will do everything we can to assist by providing additional brochures, product videos, or arrange video conference in your preferred date and time.

We thank you for your kind understanding, and all the necessary plans will be made to make sure the business won’t be affected during this time.

Hope everyone is in good health and may God bless us all

Sincerely,

ZIPP GROUP

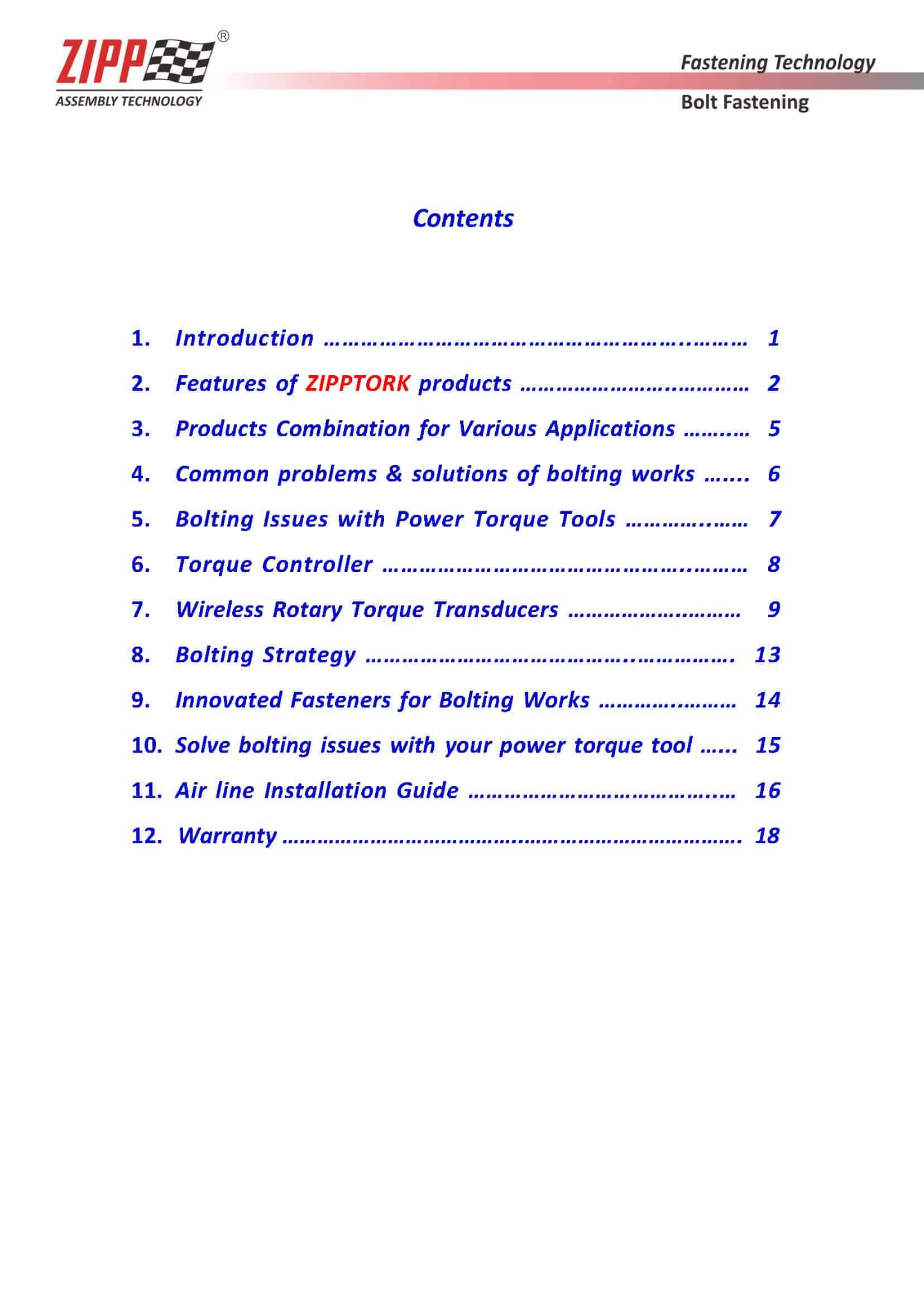

System settings and configurations on the tablet

How to pair wireless transducer on the tablet with Dongle/Transceiver installed

Static Mode – Use with the torque wrench

Dynamic Mode – Use with non-shut off pulse tool

Torque & Angle Mode – Use with torque wrench or click wrench

Dynamic torque Mode – Use with clutch type tool

Dynamic torque Mode – Use with Air impact wrench

Dynamic torque Mode – Use with auto shut off pulse tool

Job sequence setup – Use with click wrench with torque and angle

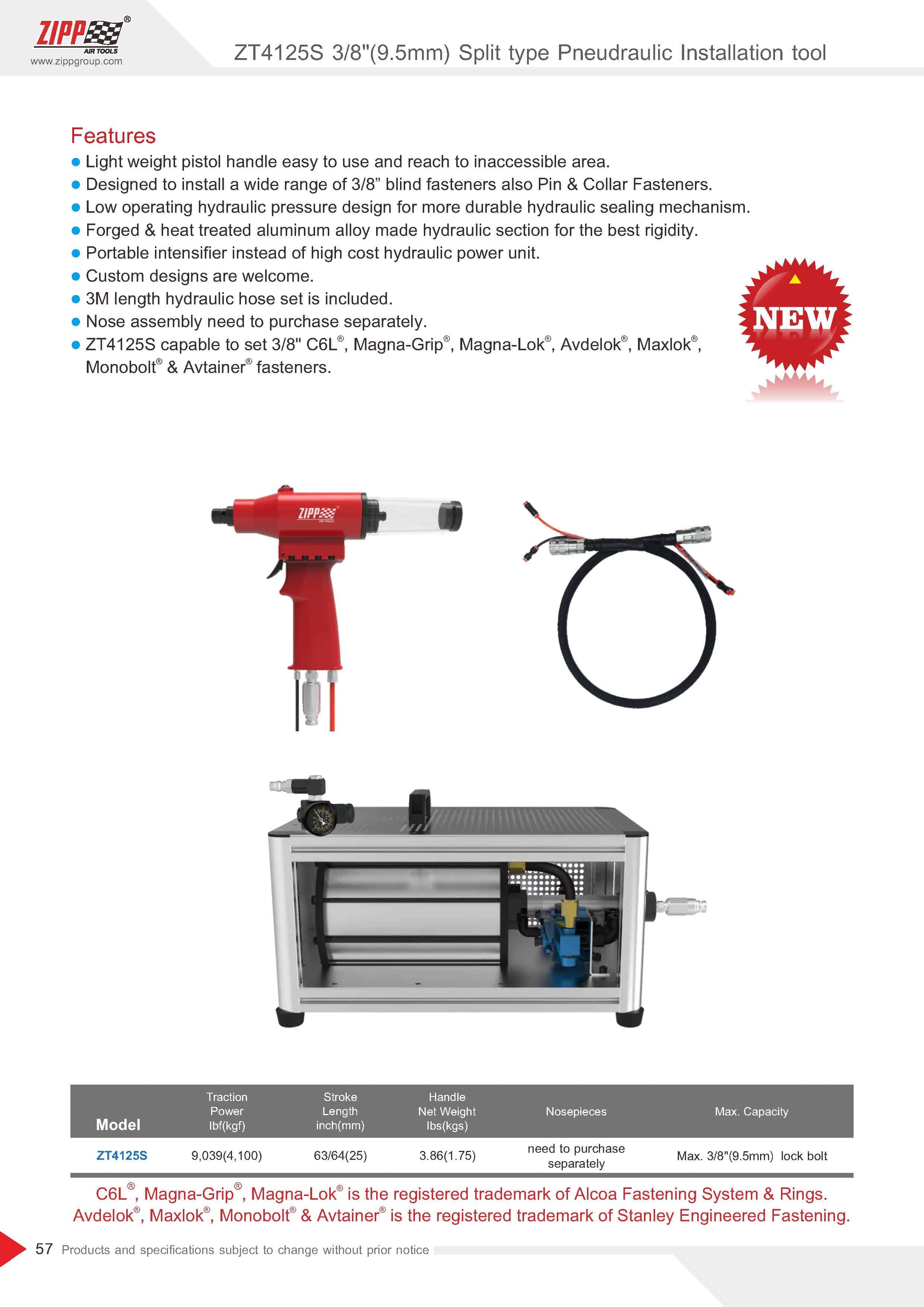

Split & Inline riveters designed for ergonomic and limited space

Split riveters are designed specifically for various types of rivets with minimal access. The tools transmit power from the power unit through a flexible hose to a small, lightweight head. By utilizing the proper pulling head, design problems and operator fatigue can be reduced dramatically.

Brand new cordless blind riveter available now

ZIPPTORK Smart Torque Controller designed for Industrial assembly process with precision tightening technology that reduces downtime and tool costs

Innovated new products will be announced at the MOTEK SHOW 2018 in Stuttgart, Germany

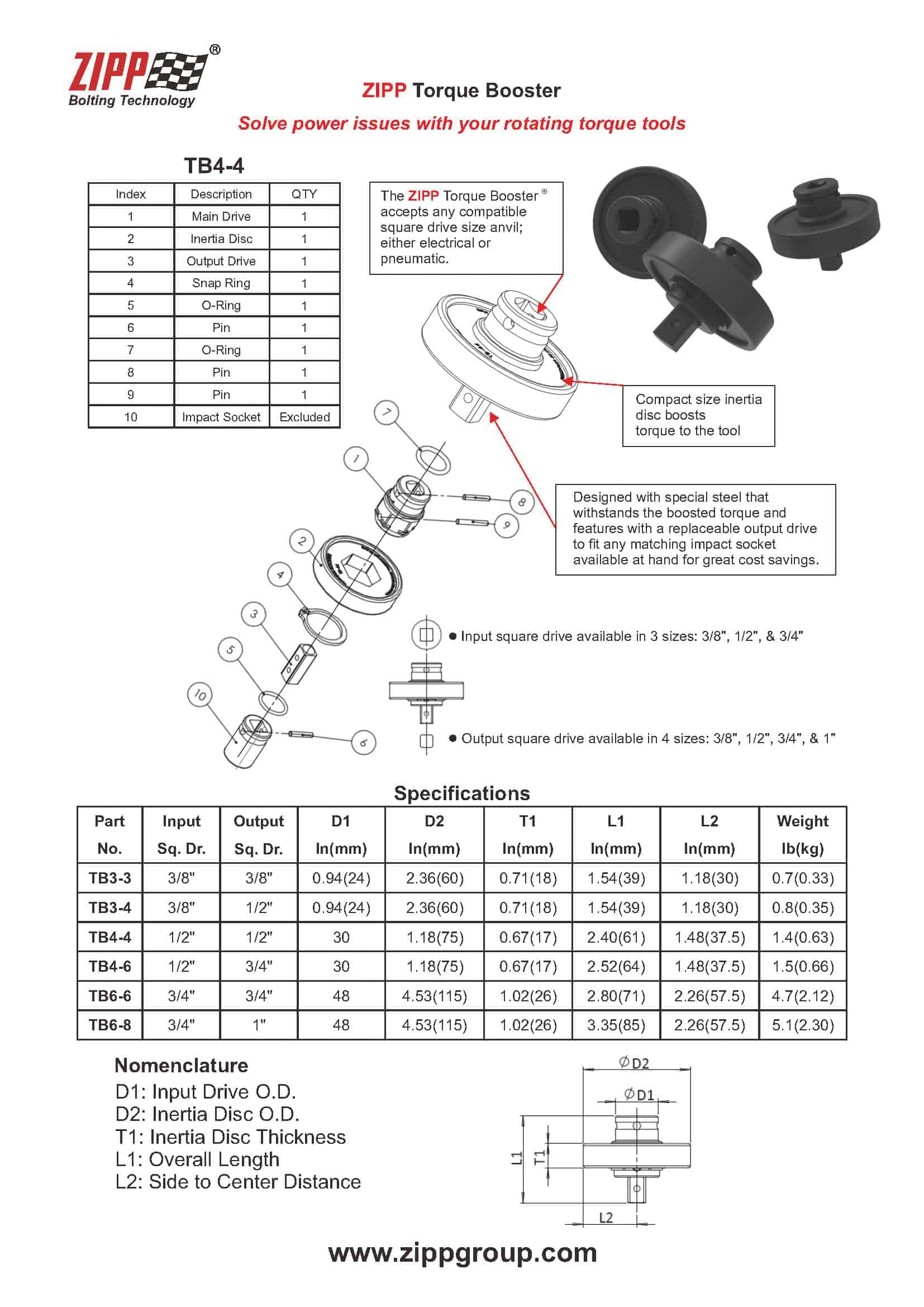

ZIPP Torque Booster Features

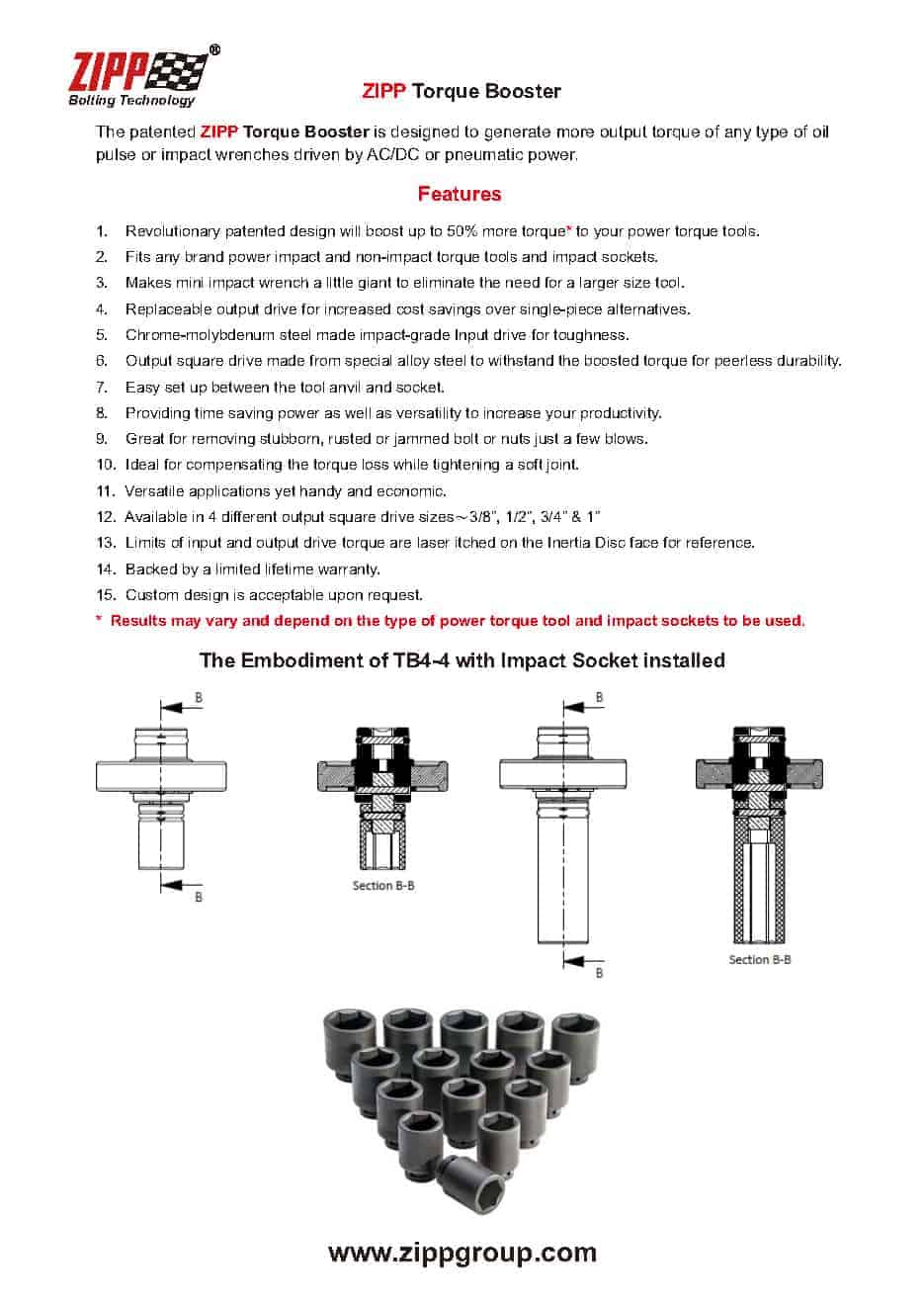

The Embodiment of TB4-4 with Impact Socket installed

The patented ZIPP Torque Booster is designed to generate more output torque of any type of pulse or impact wrenches driven by AC/DC or pneumatic power.

1. Revolutionary patented design will boost up to 50% more torque* to your power torque tools.

2. Fits any brand power impact and non-impact torque tools and impact sockets.

3. Makes mini impact wrench a little giant to eliminate the need for a larger size tool.

4. Replaceable output drive for increased cost savings over single-piece alternatives.

5. Chrome-molybdenum steel made impact-grade Input drive for toughness.

6. Output square drive made from special alloy steel to withstand the boosted torque for peerless durability.

7. Easy set up between the tool anvil and socket.

8. Providing time-saving power as well as versatility to increase your productivity.

9. Great for removing stubborn, rusted or jammed bolt or nuts just a few blows.

10. Ideal for compensating the torque loss while tightening a soft joint.

11. Versatile applications yet handy and economic.

12. Available in 4 different output square drive sizes~3/8”, 1/2”, 3/4” & 1”

13. Limits of input and output drive torque are laser etched on the Inertia Disc face for reference.

14. Backed by a limited lifetime warranty.

15. Custom design is acceptable upon request.

* Results may vary and depend on the type of power torque tool and impact sockets to be used.